Industrial Plant

Reactor <Capacity 5~40m³>

Condenser <ø750 x 3500L>

Heater Exchanger <ø1500 x 2500L>

Steam Drum <ø800 x 2500H>

Preheater <ø1300 x 1200L>

Vacuum system

Storage Tanks <100, 200, 300m³>

Chemical Plant

Fine Chemical Manufacturing Facility

Polymer Manufacturing Facility

Membrane Purification Facility

Distillation Column

Waste Organic Solvent Purification Facility

Waste Secondary Battery Recycling Facilities

Crushing Equipment

Separation Equipment

Dewatering Equipment

Post-treatment Equipment

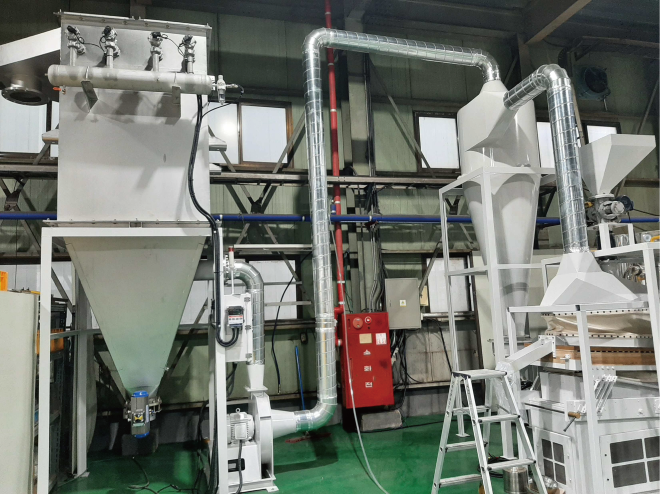

Engineering

Based on our extensive plant construction track record and engineering experience, we work in close cooperation with our customers to provide technical support services including design, commercial plant construction, and commissioning.

Powder Testing Equipment

Air Jet Mill (Dual Chamber Type)

| Application | High-purity material milling where prevention of impurity contamination is required: cathode materials, pharmaceuticals, high-functional foods, and cosmetic material processing |

| Operating Pressure | 8.0~10kg/㎠ |

| Throughput | 3~300kg/hr |

| Particle Size (Before Milling) | 50~100㎛ |

| Particle Size (After Milling) | 1~50㎛ |

Air Jet Mill (Vertical Classifier Type)

| Application | High-purity material milling where prevention of impurity contamination is required: rare-earth permanent magnets, pharmaceuticals, and cosmetic material processing |

| Operating Pressure | 8.0~10kg/㎠ |

| Throughput | 3~100kg/hr |

| Particle Size (Before Milling) | Under 50㎛ |

| Particle Size (After Milling) | 1~10㎛ |

Air Classifing Mill System

| Application | Milling with a built-in classifier enabling simultaneous grinding & classification: processing of battery anode & cathode materials, compounds, and inorganic materials |

| Feed Particle Size | 1.0mm~50㎛ |

| Rotational Speed | 7,000rpm |

| Throughput | 5~300kg/hr |

| Particle Size (Before Milling) | 1.0mm |

| Particle Size (After Milling) | 50㎛ |

Fine Impact Mill

| Application | Meshless impact-type milling & deagglomeration: processing of waste batteries, pharmaceuticals, and cosmetic materials |

| Feed Particle Size | 10~100㎛ |

| Rotational Speed | 10,000rpm |

| Throughput | 100~300kg/hr |

| Particle Size (Before Milling) | 2.0mm |

| Particle Size (After Milling) | 5~20㎛ |

Non-Stop Blade Mill

| Application | Deagglomeration, agriculture, dyes, pigments, and coarse grinding: processing of minerals, pharmaceuticals, and cosmetic materials |

| Feed Particle Size | 100~300㎛ |

| Rotational Speed | 4,900rpm |

| Throughput | 50~1,000kg/hr |

| Particle Size (Before Milling) | 20mm |

| Particle Size (After Milling) | 50㎛ |

Polymer Mill

| Application | Milling and chopping system for high-strength polymers such as carbon or glass fiber, natural rubber, synthetic adhesives, mixed waste, etc. |

| Model | MPCM-250 |

| Rotational Speed | 10~40 rpm |

| Capacity | 250 kg/hr |

| Power | 15 kW |

| Feed Particle Size | Under 150 mm |

| Output Particle Size | Under 100 μm |

| Dimensions | 1950 (L) × 750 (D) × 1387 (H) mm |

* Capacity may vary depending on material properties, feed size, and particle size requirements.

Separator

| Application | Separation of waste battery materials, etc. |

| Throughput | 1,000kg/hr |

| Overall Dimensions | 600mm × 1,000mm |

| Configuration | Separator, dust collector, turbo blower |

Muller Mixer

| Material | Gun Powder |

| Throughput | 60kg/hr (Delay composition 50kg + Binder 10kg) |

| Overall Dimensions | Mixing Drum : Φ1,000 × 500h | Wheel : Φ406 × 76t |

| Rotational Speed | Pre-mixing/Discharge 4rpm, Mixing 17~26rpm, explosion-proof control panel applied |

Powder Particle Size & Physical Property Analyzers

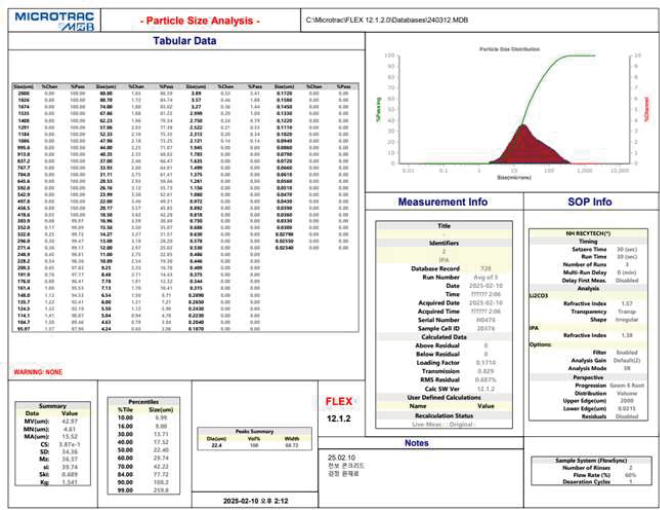

Size & Shape particle analyzer

Particle shape can affect the performance of the final product, and through various analysis parameters for size and shape, we provide data that helps establish product standards in a more detailed and suitable way.

Instrument Information

| Model No | Sync 3R |

| Maker | Microtrac (USA) |

Measurement Item Specification

| Method | Fraunhofer & Mie Scattering |

| Range | 0.2∼2,000 ㎛ (Wet) |

| Optical system |

Three semiconductor lasers (Solid laser: 780mm wavelength) First laser : 0°∼80° Detection: micron size Second laser: 80°∼100° Detection: sub micron size Third laser : 100°∼162° Detection: nano size Automatic Laser Alignment |

| Wet dispersion | Full automatic system |

Material/Powder Character Analyzer

Through analysis of material properties, we can propose solutions based on rational evidence to accurately address customer needs.

In addition, by analyzing and providing data on the properties of results obtained through milling, we contribute to enabling a scientific approach to handling materials.

Instrument Information

| Model No | PT-X |

| Maker | Hosokawa micron coporation (Japan) |

Measurement Items

| 1 | Angle of repose |

| 2 | Angle of fall |

| 3 | Angle of difference |

| 4 | Angle of spatula |

| 5 | Aerated bulk density |

| 6 | Packed bulk density |

| 7 | Compressibility |

| 8 | Cohesion |

| 9 | Uniformity |

| 10 | Dispersibility |

Pilot Test Facilities

Continuous Separation System

Continuous Distillation System

Reaction System

Catalytic Reaction System

Organic Compound & Moisture Analyzers (Measurement)

Organic Compound Analyzer

Moisture Analyzer (Measurement)